We understand the importance of a high speed to market.

Perhaps you are working on a project where the PP build is quickly coming up and there is simply no time left for normal injection moulding to prove the products fit and function.

As one of the first companies in the world we are now combining traditional injection moulding with 21st century production techniques.

This makes it possible for us to offer something truly amazing.

Injection mould tools capable of making up to 300 parts in only [ut_highlight color=”#ffffff” bgcolor=”#dd3333″] 1 week [/ut_highlight] .

(depending on your resin and surface requirements)

Good material selection is important for success when injection

molding using 3D printed molds.

ABS is often the best choice for printing. It combines

strength and toughness together with high temperature resistance.

[ut_one_half]

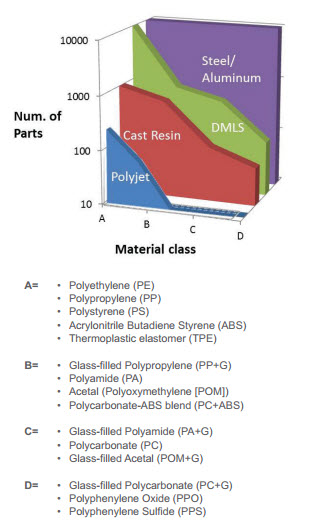

Part materials:

The best materials for creating injection molded parts are those that

have reasonable molding temperatures (< 300 °C) and good flow behaviour.

Ideal candidates are:

• Polyethylene (PE)

• Polypropylene (PP)

• Polystyrene (PS)

• Acrylonitrile Butadiene Styrene (ABS)

• Thermoplastic elastomer (TPE)

• Polyamide (PA)

• Polyoxymethylene or Acetal (POM)

• Polycarbonate-ABS blend (PC-ABS)

• Glass-filled polypropylene or glass-filled resin (G)

[/ut_one_half]

[ut_one_half_last]

Tool life:

[/ut_one_half_last]

[/ut_one_half_last]

Achievable accuracy:

Tool inserts are produced within an accuracy of ± .09 mm (± .0035 in.) or ± .0015 mm/mm (± .0015 in/in),whichever is greater. (Accuracy is geometry dependent. Achievable accuracy specification derived from statistical data at 95% dimensional yield.)

Build envelope:

Core = 914 x 610 x 914 mm

Cavity = 914 x 610 x 914 mm

Examples of use:

[su_custom_gallery source=”media: 591,587,586″ width=”190″ height=”190″ title=”never”]