Getting that perfect thread in a moulded plastic part takes some skills and know how.

Unfortunately many toolmakers still do not quite know how to achieve this.

The secret is in most cases to use a process called Orbital tapping.

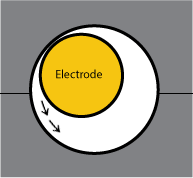

Orbital tapping is accomplished by utilizing a vastly

undersized electrode, whose O.D. is

small enough to drop down vertically

full depth into the tap drill sized hole.

A planetary motion is then introduced feeding radially outward

until the finished thread size is reached.

Orbit tapping engages the electrode over the entire

depth of the hole, allowing a much larger “frontal burn” area, while spreading

the electrode wear over the entire surface of the electrode.

This reduces the problem with uneven wear and gives a very nice result.

This is something you should make sure any toolmaker you work with is aware of, and have the equipment for.

A good CNC EDM machine is crucial.

Please feel free to contact us at The Tool Hub if you have any questions or need support.