When ultra efficient and even cooling is required we recommend one of our latest technology advancement. DMLS.

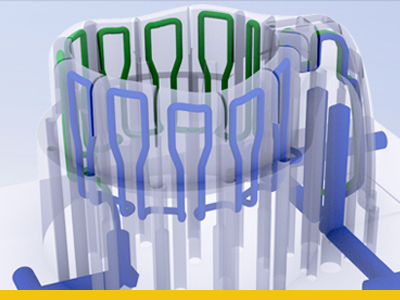

By using DMLS (Direct Metal Laser Sintering) we are able to build core and cavity inserts in a number of materials.

| Material | Info |

|---|---|

| Stainless steel 17-4 | • 20 or 40 Micron Layers • 20-25 HRC Built |

| Stainless steel 15-5 | • 20 or 40 Micron Layers • 30-35 HRC Built • Post Hardened to 40 HRC |

| Stainless steel 316L | • High hardness and toughness • Low Carbon • 40 Micron Layers |

| Steel DIN 2709 | • 20 or 40 Micron Layers • 33-37 HRC Built • Post Hardened to 50-54 HRC |

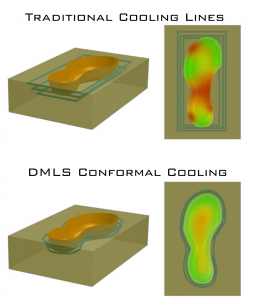

This gives you the option of having cooling circuits that completely follows the contour of the part thus giving excellent efficiency and evenness in the heat transfer.

Surface quality:

The DMLS parts can be polished and you can expect the same surface quality as on a normal machined part.

Directly from the machine we get an Ra value of 12.5 (similar to a 400 grit paper)

Benefits:

Reduced cycle times

Decreased warping

Even cooling times over the whole melt volume.

Post process:

The inherent design freedom of DMLS reduces the need for secondary processes.

For example, text may be incorporated in a CAD file to build an engraved part. However, when desired or needed, parts built on a DMLS machine are secondary process friendly.

The options include machining, tapping, welding, coating, plating and/or texturing, EDM, and engraving.

Polishing requires some pre-build planning.

DMLS parts can be polished to a mirror finish, but the size of the part must be altered in the CAD file (.01 up to .030 depending on desired finish) to account for material removed during the polishing process.

Cost and time rule of thumb:

When we work with DMLS a simple calculation method is:

24 H of production per Kg of insert

2000 USD per Kg of insert

Example:

An insert in stainless steel with dimensions 100mm x 100mm x 100mm will require 1 week of production time and cost 14000 USD

The price is slowly coming down and for small inserts this is already a good production option.