There are many factors to consider when you are trying to get a cosmetically correct part made from poly carbonate.

For a toolmaker gating and venting are 2 of the most important.

Gate:

At The Tool Hub we recommend you to do all you can not to restrict the flow path.

That includes:

- Increasing the sprue bushing to the correct size for the material being used.

- The diameter of the sprue needs to be bigger so the orifice in the nozzle can be bigger. That will eliminate a shear point in the flow path

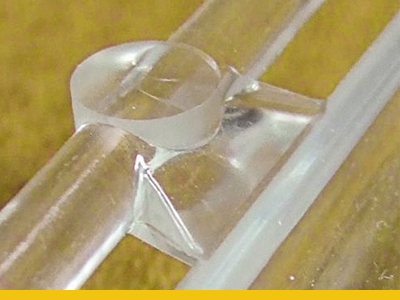

- Indirect Edge/Wedge gates are recommended

- Edge depth = 90% of the wall thickness

- Edge width for small parts = edge depth

- Edge width for medium parts = 2 x edge depth

- Edge width for large parts = 3 x edge depth

- Land length = 0,5 x edge depth

- The runner should always be full round when feeding an edge gate so the edge gate can come off the center of the runner and fill each cavity through an abrupt transition instead of through a ramp design.

- The length of the cold well after the gate should be twice the width of the gate.

Vents:

Vents for poly carbonate should be machined to 0,07mm deep and as wide as the runner.

As you know there are many more factors to consider so please do not hesitate to contact us at The Tool Hub for any questions.