Part and Mold Design for optimal 2K success.

Part Design Basics

•The wall thickness of the substrate and overmold should be as uniform as possible to obtain the best molding cycle time. Wall thicknesses ranging from 1.5 mm-3 mm will ensure good bonding in most overmolding applications. If the part requires the use of thick TPE sections, they should be cored out to minimize shrinkage problems, reduce the part weight and lower cycle time.

• Transitions between wall thickness should be gradual to reduce flow problems, such as back fills and gas traps.

• Deep, unventable blind pockets or ribs should be avoided.

• Long draws should have a 3-5° draft per side to aid component ejection.

• The TPE thickness should be less than or equal to the thickness of the substrate to prevent warpage; this is especially critical for long, flat geometries.

Materials

At The Tool Hub we see and use allot of different thermoplastic elastomers if we are asked to recommend something we would say that Kraiburg and GLS are two very good options.

They both have solutions that provide excellent adhesion to a wide variety of substrates,from polyolefins, such as polypropylene and polyethylene, to engineering resins,

such as PC, ABS, acetal and nylon.

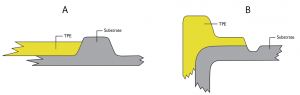

Shut-Off Designs

There are two different types of shut-off designs with the purpose of minimizing flashing of the TPE or reducing the chance of delamination.

To reduce the opportunity for peeling, the overmold should be designed in

accordance with the following guidelines:

• The surface of the TPE should be flush with the non-overmolded section of the substrate.

• The edge of the TPE should be at a deeper level than the surface of the non-overmolded

section of the substrate.

(see A below)

To reduce the probability of flashing the mold, the overmold should be designed

with the following guidelines:

• Provide a 0.4 mm – 0.8 mm deep groove on the substrate, along the edge of

the TPE overmold. The steel should have positive shut-off in the groove.

(see B below)

General Mold Design Considerations

• The viscosity of TPEs is very shear dependent and this should be considered

when designing the molds and setting the molding process conditions.

Start with small TPE injection gates to obtain best TPE fill with minimum cosmetic gate vestige.

• Gates should be located at the thickest TPE wall section.

• Flow ratios should not exceed 150: 1L/T as an absolute maximum for most overmolding

applications.

Gates

The type of gate is dependent on both part and tool design and the gate location is

equally important. To prevent the chances of jetting, locate the gate entrance in an area

where the flow will impinge on a cavity wall.

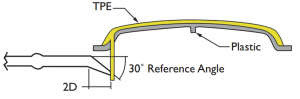

For automatically degating tools, the highly elastic nature of softer TPEs makes submarine gate designs or three plate tools with selfdegating

drops more difficult. Higher hardness and filled grades usually have lower

ultimate elongation and therefore are more easily degated. To assure the gates will

break at a specific location, they should have a short land length to create a high stress

concentration.

2K submarine gate seen below

2 Common problems

Poor adhesion:

Solution

Make sure you have selected the correct material suitable to your substrate.

Injection speed is too slow and melt temperature is too low.

Flash over on the substrate:

Solutions in the tool

• Check mold fit.

• Re-cut the tool to obtain complete shutoff with minimum of 0.05 mm interference into the substrate.

• Check for substrate b surface steel support.

• Reduce thickness of the vents to max 0.025mm

Solutions on the press

• Reduce 1st stage injection pressure and fill time.

• Reduce injection speed.

• Reduce TPE melt temperature in 10˚C increments.

• Increase machine tonnage.

Good luck with your 2K project and please contact us if you require any help.

We have a long successful history for all types of 2K solutions including:

• Insert moulding – Overmoulding with multiple tools

• Insert moulding – Overmoulding with 1 single tool

• Standard Multi shot with rotating halves

• Standard Multi-shot with sliding cores

• Simultaneous Multi-shot moulding

The Tool Hub

Always there when you need us!