There are a few things to take in to consideration when trying to use a submarine gate solution with a Polycarbonate material.

As the material is hard and very resistant to flex it is important that a steep gate angle is used from the parting line and on to the part surface.

This minimizes the amount of deflection needed to remove the gate from the mold.

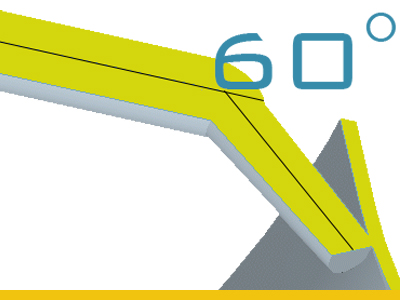

At The Tool Hub we recommend an angle of 60 degrees with an absolute minimum of 55 degrees if the gate distance is kept short.

We also recommend to keep the gate as short as possible as this also reduces the amount of deflection needed.

Keep the runner area as small as possible to allow maximum flex, and only if a pressure drop study reveals that the section is too small increase the area.

[ut_blockquote_left] Minimum 60 degrees – Short gate distance – Small runner area[/ut_blockquote_left]